Many people think that 3D printing is to extrude materials from hot nozzles and stack them into shapes, but in fact 3D printing is far more than that! Today, Antarctic Bear will introduce seven kinds of 3D printing processes. Even 3D printing can clearly distinguish different 3D printing processes.

In fact, 3D printing, also known as additive manufacturing, is a general term, covering several completely different 3D printing processes. These technologies are worlds apart, but the key process is the same. For example, all 3D printing starts with a digital model, because the technology is digital in nature. Parts or products are originally electronic files designed by computer aided design (CAD) software or obtained from digital parts library. Then the design file is decomposed into slices or layers by special construction preparation software for 3D printing, and the path instructions to be followed by the 3D printer are generated. Next, you will understand the differences between these technologies and the typical uses of each technology.

Why are there seven types?

The types of additive manufacturing can be classified according to the products they produce or the types of materials they use, and the International Organization for Standards (ISO) divides them into seven general types (but these seven 3D printing categories can hardly cover more and more technical sub-types and mixed technologies). :

● Material extrusion

● Reduction polymerization

● Powder bed fusion

● Material spraying

● Adhesive spraying

● Directed energy deposition

● Sheet lamination

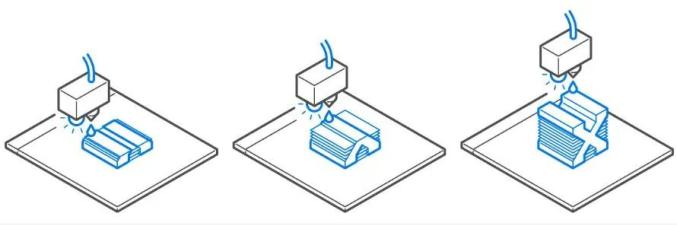

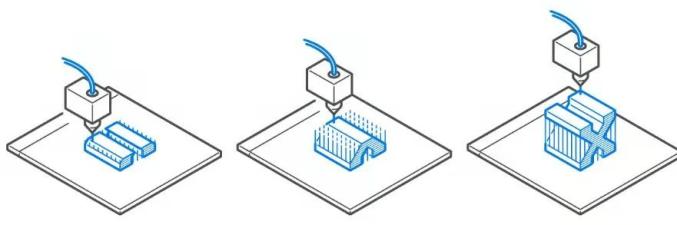

First, material extrusion

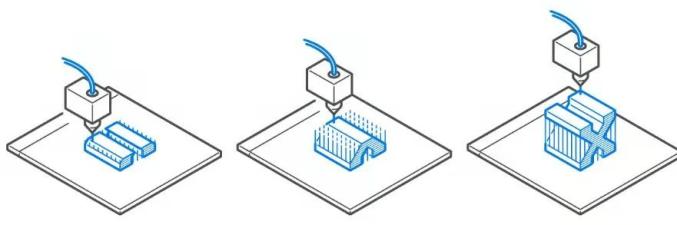

△ Material extrusion 3D printing

Material extrusion as the name implies: material is extruded through a nozzle. Usually, this material is a plastic filament, which is melted and extruded through a heated nozzle. The printer places materials on the building platform along the process path obtained by software. The filament then cools and solidifies to form a solid object. This is the most common form of 3D printing. At first glance, it sounds simple, but considering the extruded materials, including plastics, metals, concrete, bio-gel and various foods, it is actually a very broad category. The price of this type of 3D printer ranges from $100 to seven figures.

● Subtypes of material extrusion: fused deposition modeling (FDM), building 3D printing, micro 3D printing and biological 3D printing.

● Materials: plastic, metal, food, concrete, etc.

● Dimensional accuracy: 0.5% (lower limit: ±0.5mm)

● Common applications: prototype, electrical enclosure, shape and fit test, fixture and fixture, investment casting model, house, etc.

● Advantages: 3D printing method with the lowest cost and wide range of materials.

● Disadvantages: Generally, the material performance is low (strength, durability, etc.), and the dimensional accuracy is usually not high.

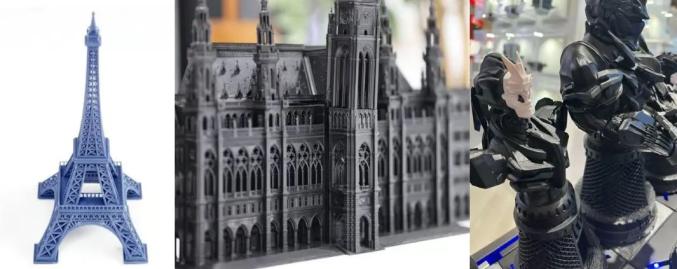

1. Fused Deposition Molding (FDM)

△FDM parts can be made of metal or plastic on various 3D printers.

FDM 3D printer is a multi-billion dollar market with thousands of machines, ranging from basic models to complex models of manufacturers. The FDM machine is called Fuse Manufacturing (FFF), which is exactly the same technology. Like all 3D printing technologies, FDM starts with a digital model and then converts it into a path that a 3D printer can follow. Using FDM, one filament (or several filaments at a time) on the bobbin is loaded into a 3D printer and then sent to the printer nozzle in the extrusion head. The nozzle or nozzles of the printer are heated to the required temperature to soften the filament, thus connecting successive layers to form a solid part.

When the printer moves the extrusion head along the specified coordinates on the XY plane, it will continue to lay the first layer. Then the extrusion head rises to the next height (Z plane), and the process of printing the cross section is repeated, building layer by layer until the object is fully formed. Depending on the geometry of the object, it is sometimes necessary to add a support structure to support the model when printing, for example, if the model has a steep overhang. These supports are removed after printing. Some supporting structure materials can be dissolved in water or another solution.

△FDM 3D printers provide a wide range of machines for amateurs, small businesses and manufacturers (sources: Creality, Raise3D, Stratasys).

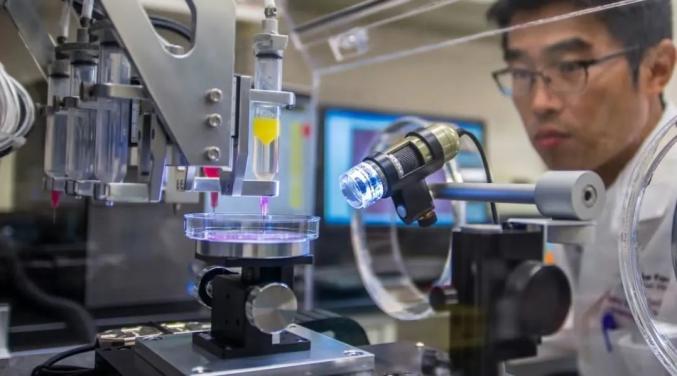

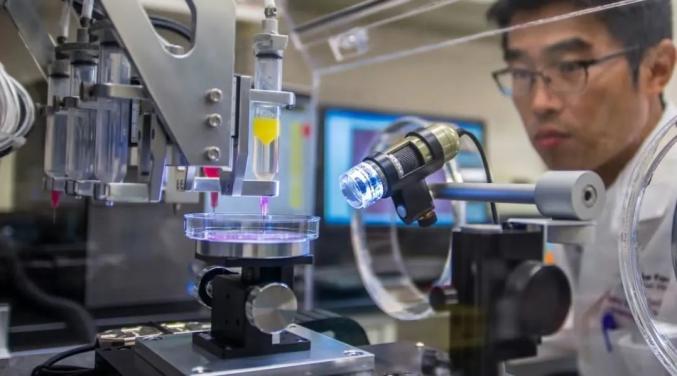

2.3D biological printing

△3D bio-printing is similar to traditional 3D printing, but the raw materials are quite different.

3D biological printing or biological 3D printing is an additive manufacturing process in which organic or biological materials (such as living cells and nutrients) are combined to create a natural three-dimensional structure similar to tissues. In other words, bioprinting is a kind of 3D printing, which can produce anything from bone tissues and blood vessels to living tissues. It is used in various medical research and applications, including tissue engineering, drug testing and development, and innovative regenerative medicine therapy. The actual definition of 3D bioprinting is still developing. Essentially, the working principle of 3D bio-printing is similar to FDM 3D printing, and it belongs to the material extrusion series. (Although extrusion is not the only bio-printing method)

3D bio-printing uses the material (bio-ink) discharged from the needle to create a printed layer. These materials, called bio-inks, are mainly composed of living substances, such as cells in carrier materials, such as collagen, gelatin, hyaluronic acid, silk, alginate or nano-cellulose, which serve as molecular scaffolds for structural growth and nutrients.

3. Building 3D printing

△ Building 3D printing

Building 3D printing is a rapidly developing field of material extrusion. This technology involves the use of super-large 3D printers (usually up to tens of meters) to extrude building materials such as concrete from nozzles. These machines usually appear in the form of gantry or robotic arm systems. 3D architectural printing technology is now used in residential buildings, architectural features and construction projects from wells to walls. Some researchers say that it may significantly change the whole construction industry, because it reduces the demand for labor and construction waste.

There are dozens of 3D printed houses in the United States and Europe, and 3D building technology is being researched and developed, which will use materials found on the moon and Mars to build habitats for future expeditions. Printing with local soil instead of concrete as a more sustainable building method has also attracted attention.

Second, reduction polymerization

△ Reduction polymerization using laser

Barrel polymerization (also known as resin 3D printing) is a series of 3D printing processes, which uses a light source to selectively cure (or harden) photopolymer resin in a barrel. In other words, light is precisely directed at a specific point or area of liquid plastic to harden it. After the first layer is cured, the building platform will move up or down (depending on the printer) by a small amount (usually between 0.01 and 0.05 mm), and the next layer will be cured and connected with the previous layer. This process is repeated layer by layer until a 3D part is formed. After the 3D printing process is completed, the object is cleaned to remove the remaining liquid resin and post-cured (in the sun or ultraviolet room) to enhance the mechanical properties of the parts.

The three most common forms of barrel polymerization are stereolithography (SLA), digital light processing (DLP) and liquid crystal display (LCD), also known as mask stereolithography (MSLA). The fundamental difference between these types of 3D printing technologies lies in the light source and the way it is used to cure the resin.

△ vats polymerization uses light to harden photosensitive resin layer by layer.

Some 3D printer manufacturers, especially those that manufacture professional 3D printers, have developed unique and patented photopolymerization variants, so you may see different technical names in the market. Carbon, an industrial 3D printer manufacturer, uses a barrel polymerization technology called Digital Photosynthesis (DLS), Origin of Stratasys calls it Programmable Photopolymerization (P3), Formlabs provides a technology called Low-Force Stereolithography (LFS), and Azul 3D is the first to commercialize the barrel polymerization in the form of large-area rapid printing (HARP). There are also photolithography-based metal manufacturing (LMM), projection micro-stereolithography (PμSL) and digital composite manufacturing (DCM), which is a technology of filling photopolymer and can introduce functional additives (such as metal and ceramic fibers) into liquid resin.

● Types of 3D printing technology: Stereolithography (SLA), Liquid Crystal Display (LCD), Digital Light Processing (DLP), Micro Stereolithography (μSLA), etc.

● Material: photopolymer resin (castable, transparent, industrial, biocompatible, etc.)

● Dimensional accuracy: 0.5% (the lower limit is 0.15mm or 5nm, using μSLA).

● Common applications: injection molding polymer prototypes and end-use parts, jewelry casting, dental applications, consumer goods.

● Advantages: smooth surface finish and fine feature details.

1. Stereolithography (SLA)

△ Stereolithography (SLA) Examples of SLA 3D printing from 3D Systems, DWS and Formlabs.

SLA is the first 3D printing technology in the world. Stereolithography was invented by Chuck Hull in 1986. He applied for a patent for this technology and set up 3D Systems Company to commercialize it. Today, this technology can be used by enthusiasts and professionals from many 3D printer manufacturers. SLA uses laser beam to aim at a barrel of resin, selectively solidifies the cross section of the object in the printing area, and builds it layer by layer. When most SLA printers use solid-state lasers to cure components. One disadvantage of this barrel polymerization is that compared with our next method (DLP), the point laser may take longer to track the cross section of the object, and the latter will flash light to immediately harden the whole layer. However, laser can produce stronger light, which is required by some engineering-grade resins.

△SLA 3D printer uses one or more lasers to track and cure a single layer of resin at one time.

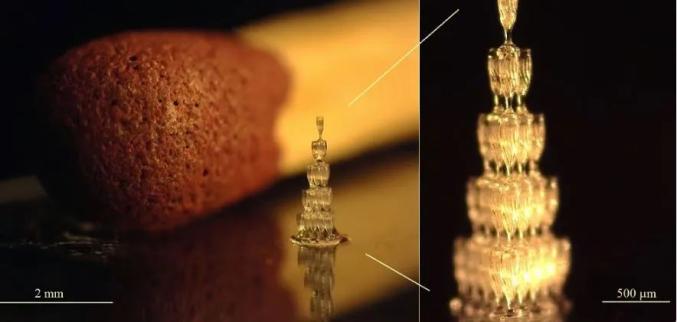

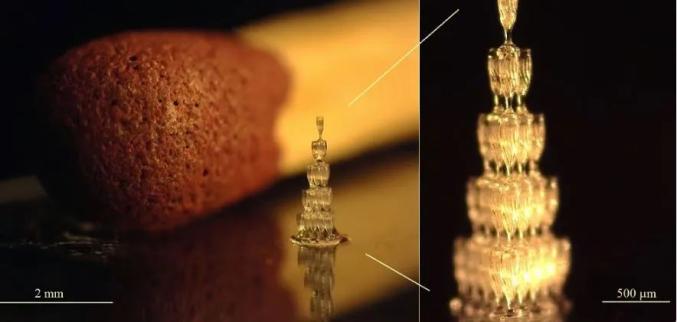

Micro-stereolithography (μSLA)

Micro-stereolithography technology can print micro-parts, and the resolution is between 2 microns (μm) and 50 microns. For reference, the average width of human hair is 75 microns. It is one of the "micro 3D printing" technologies. μSLA involves exposing photosensitive material (liquid resin) to ultraviolet laser. The difference lies in the special resin, the complexity of laser and the addition of lens, which will produce almost incredible small light spots.

△Nanoscribe and Microlight3D are two leading manufacturers of TPP 3D printers (source: Nanoscribe and Microlight3D).

Two-photon polymerization (TPP)

Another micro 3D printing technology, TPP (also called 2PP), can be classified as SLA, because it also uses laser and photosensitive resin, and it can print parts smaller than μSLA, as small as 0.1 micron. TPP uses pulsed femtosecond laser to focus on a narrow spot in a large barrel of special resin. This point is then used to cure a single 3D pixel, also called a voxel, in the resin. By curing these nano-scale to micron-scale voxels layer by layer in a predefined path. TPP is currently used in research, medical applications and the manufacture of micro parts, such as microelectrodes and optical sensors.

△ Micro 3D printing: TPP technology

2. Digital Light Processing (DLP)

△ DLP 3D printing parts of △Anycubic, Carbon and ETEC

DLP 3D printing uses a digital light projector (instead of a laser) to flash a single image of each layer on a layer or resin at the same time (or to expose a larger part for multiple times). DLP (more common than SLA) is used to produce larger parts or larger parts in a single batch, because no matter how many parts are in construction, each layer needs exactly the same exposure time, which is more efficient than the point laser method in SLA. The image of each layer consists of square pixels, resulting in a layer formed by small rectangular blocks called voxels. Light is projected onto the resin using a light emitting diode (LED) screen or a UV light source (lamp) and onto the construction surface through a digital micromirror device (DMD).

△ Digital Light Processing (DLP) resin 3D printer has a hobby version and a complete manufacturing machine.

Modern DLP projectors usually have thousands of micron-sized LEDs as light sources. Their on-off states are independently controlled, which can improve the XY resolution. Not all DLP 3D printers are the same. The power of light source, the lens it passes through, the quality of DMD and many other parts that make up a machine worth 300 dollars are quite different compared with a machine worth more than 200,000 dollars.

Top-down DLP

The light source of some DLP 3D printers is installed on the top of the printer, and shines down on the resin barrel instead of up. These "top-down" machines flash one layer of images from the top, curing one layer at a time, and then put the cured layer back in the vat. Every time the building board is lowered, the recoating machine installed at the top of the vat will move back and forth on the resin to level the new layer. According to the manufacturer, because the printing process will not resist gravity, this method can produce more stable parts output for larger prints. There is a limit to how much weight can be hung vertically from the building board when printing from bottom to top. The resin barrel also supports printed parts during printing, which reduces the need for supporting structures.

△BMF’s MicroArch S230 can print detailed parts of polymers or ceramics as small as 2 microns (source: BMF).

Projection microlithography (PμSL)

As a unique type of barrel aggregation itself, PμSL is classified as a subcategory of DLP. This is another micro 3D printing technology. PμSL uses ultraviolet rays from the projector to cure the specially formulated resin layer in micron scale (2 micron resolution and as low as 5 micron height). This additive manufacturing technology is developing continuously because of its low cost, accuracy, speed and the range of materials (including polymers, biomaterials and ceramics). It has shown the application potential from microfluidic and tissue engineering to micro-optics and biomedical micro-devices.

Metal Manufacturing Based on Lithography (LMM)

This is another "distant relative" of DLP. This method of 3D printing using light and resin can create tiny metal parts for applications such as surgical tools and micromechanical parts. In LMM, metal powder is uniformly dispersed in photosensitive resin, and then selectively polymerized by blue light exposure through a projector. After printing, the polymer components of the blank parts are removed, leaving all-metal degreased parts, which are completed in the sintering process in the furnace. Raw materials include stainless steel, titanium, tungsten, brass, copper, silver and gold.

△ Micro-metal 3d printing parts made on Incus 3D printing with LMM technology.

3. Liquid crystal display (LCD)

△ LCD 3D printing components from Elegoo, Photocentric and Nexa3D.

Liquid crystal display (LCD), also known as mask stereolithography (MSLA), is very similar to the above DLP, except that it uses LCD screen instead of digital micromirror device (DMD), which has a significant impact on the price of 3D printer. Like DLP, LCD photomask is digitally displayed and consists of square pixels. The pixel size of LCD photomask determines the granularity of printing. Therefore, the XY accuracy is fixed and does not depend on the zoom or zoom degree of the lens, just like DLP. Another difference between DLP printers and LCD technology is that the latter uses an array of hundreds of individual emitters instead of a single point emitting light source like a laser diode or DLP bulb.

△ Today, LCD resin 3D printing technology is shifting from consumer machines to industrial machines.

Similar to DLP, LCD can achieve faster printing time than SLA under some conditions. This is because the whole layer is exposed at one time instead of tracking the cross-sectional area with a laser spot. Due to the low cost of LCD unit, this technology has become the first choice in the field of low-cost desktop resin printers, but this does not mean that it has not been used professionally. Some industrial 3D printer manufacturers are breaking through the technical limits and achieving remarkable results.

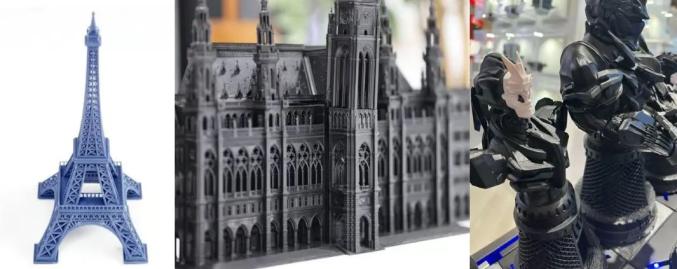

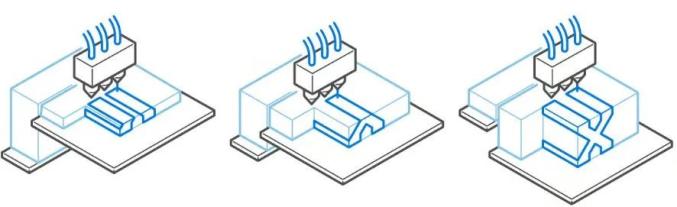

Third, powder bed fusion

△ Powder bed fusion

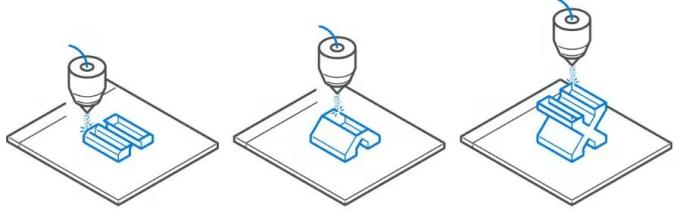

Powder bed fusion (PBF) is a 3D printing process, in which a thermal energy source selectively melts powder particles (plastic, metal or ceramic) in a construction area to create solid objects layer by layer. Powder bed fusion 3D printer spreads a thin layer of powder material on the printing bed, usually using a blade, roller or wiper. The energy from the laser fuses a specific point on the powder layer, and then another powder layer is deposited and fused to the previous layer. This process is repeated until the whole object is manufactured, and the final product is wrapped and supported by unmelted powder.

△ Metal laser powder bed fusion process

PBF can manufacture parts with high mechanical properties (including strength, wear resistance and durability) for the end use of consumer goods, machinery and tools. 3D printers in this market segment are getting cheaper and cheaper (starting at around $25,000), but it is considered as an industrial technology.

● Types of 3D printing technology: selective laser sintering (SLS), laser powder bed melting (LPBF) and electron beam melting (EBM).

● Materials: plastic powder, metal powder and ceramic powder.

● Dimensional accuracy: 0.3% (lower limit: ±0.3mm)

● Common applications: production of functional parts, complex pipes (hollow design) and small batch parts.

● Advantages: functional components, excellent mechanical properties, complex geometry.

● Disadvantages: The cost of the machine is high, usually high-cost materials, and the construction speed is slow.

1. Selective laser sintering (SLS)

△ SLS 3D printing parts of △Sinterit

Selective laser sintering (SLS) uses lasers to make objects from plastic powder. First, a box of polymer powder is heated to a temperature just below the melting point of the polymer. A very thin layer of powder material (usually 0.1 mm thick) is then deposited on the building platform using a recoating blade or wiper. The laser begins to scan the surface according to the pattern arranged in the digital model. The laser selectively sintered the powder and solidified the cross section of the object. When scanning the whole cross section, the building platform moves down one layer in height. The recoating blade deposits a new layer of powder on the recently scanned layer, and the laser sinter the next cross section of the object onto the previously solidified cross section.

△ SLS 3D printing parts can be dusted and cleaned manually or automatically.

Repeat these steps until all objects are made. The unsintered powder remains in place to support the object, which reduces or eliminates the need for supporting structures. After the parts are taken out of the powder bed and cleaned, there is no need for other necessary post-treatment steps. Parts can be polished, coated or colored. There are many differentiation factors between SL3D printers, including not only their size, but also the power and quantity of laser, the spot size of laser, the time and mode of heating bed and the distribution mode of powder. The most common materials in SL3D printing are nylon (PA6, PA12), but flexible parts can also be printed with TPU and other materials.

△SLS 3D printer uses polymer powder and laser to form solid parts.

2. Micro-selective laser sintering (μSLS)

μSLS belongs to SLS or laser powder bed fusion (LPBF) described below. It uses laser to sinter powdery materials, such as SLS, but this material is usually metal rather than plastic, so it is more like LPBF. It is another micro 3D printing technology, which can create parts with micro (less than 5 μm) resolution.

△ Metal 3D MicroPrinting from 3D microprint

In μSLS, a layer of metal nanoparticle ink is coated on the substrate and then dried to produce a uniform nanoparticle layer. Next, the laser patterned with the digital micromirror array is used to heat the nanoparticles and sinter them into a desired pattern. This set of steps is then repeated to build each layer of the 3D component in the μSLS system.

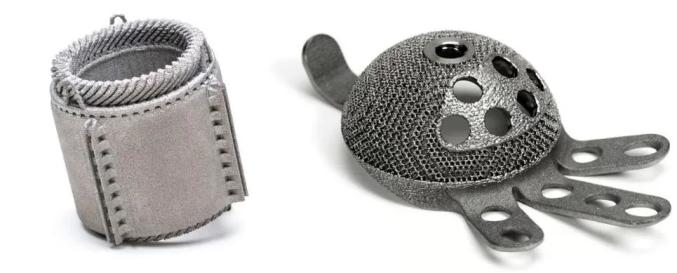

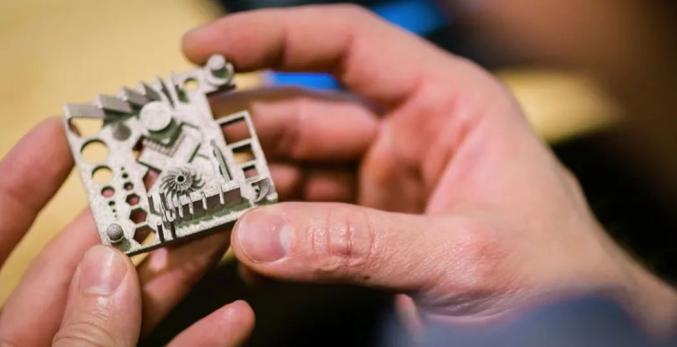

3. Laser Powder Bed Fusion (LPBF)

△ Xact Metal test piece showing SLM accuracy (source: Xact Metal)

In all 3D printing technologies, this item has the most aliases. The formal name of this metal 3D printing method is laser powder bed melting (LPBF), which is also widely known as direct metal laser sintering (DMLS) and selective laser melting (SLM). In the early days of this technology development, machine manufacturers created their own names for the same process, and these names have been used to this day. In particular, these three terms refer to the same process, even though some mechanical details are different.

As a sub-type of powder bed fusion, LPBF uses a metal powder bed and one or more (up to 12) high-power lasers. LPBF 3D printer uses laser to selectively fuse metal powder layer by layer on a molecular basis until the model is completed. LPBF is a highly accurate 3D printing method, which is usually used to create complex metal parts for aerospace, medical and industrial applications.

△Sandvik’s LPBF metal 3D printing

Like SLS, LPBF 3D printers start with a digital model divided into slices. The printer loads the powder into the building chamber, and then spreads it into a thin layer on the building board with a scraper (such as a windshield wiper) or a roller. The laser tracks the layer onto the powder. Then the building platform moves down, and then a layer of powder is coated and blended with the first layer until the whole object is built. The building chamber is closed and sealed, and in many cases it is filled with inert gas, such as nitrogen or argon mixture, to ensure that the metal will not be oxidized during the melting process and help to remove the debris during the melting process. After printing, the parts are taken out of the powder bed, cleaned and often subjected to secondary heat treatment to eliminate stress. The remaining powder is recycled.

The differentiation factors of LPBF 3D printer include the type, intensity and quantity of lasers. A small compact LPBF printer may have one 30-watt laser, while the industrial version may have 12 1,000-watt lasers. LPBF machines use common engineering alloys, such as stainless steel, nickel superalloy and titanium alloy. Dozens of metals can be used in LPBF process.

△ LPBF 3D printers from One Click Metal, Farsoon and Kurtz Ersa.

3. Electron beam melting (EBM)

△ electron beam melting (EBM)

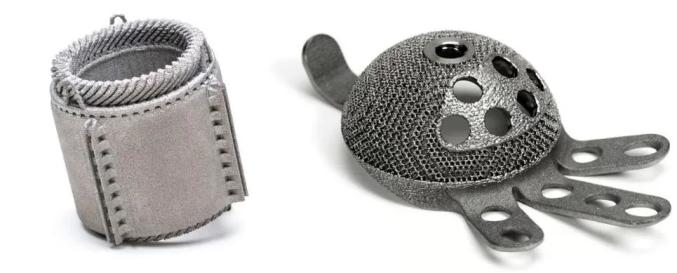

EBM, also known as Electron Beam Powder Bed Fusion (EB PBF), is a metal 3D printing method similar to LPBF, but using electron beam instead of fiber laser. This technology is used to manufacture parts, such as titanium orthopedic implants, turbine blades of jet engines and copper coils.

Electron beams generate more energy and heat, which are needed by some metals and applications. Moreover, EBM is not an inert gas environment, but is carried out in a vacuum chamber to prevent light beam scattering. The temperature of the building chamber can reach up to 1,000 °C, and even higher in some cases. Because the electron beam is controlled by electromagnetic beam, it moves faster than laser, and can even be separated to expose multiple areas at the same time.

△ Electron beam melting (EBM) metal 3D printers from JEOL, GE Additive and Wayland Additive.

One of the advantages of EBM over LPBF is that it can handle conductive materials and reflective metals such as copper. Another feature of EBM is that individual components can be nested or stacked in the building room, because they do not necessarily have to be connected to the building board, which greatly increases the volume output. Compared with laser, electron beam usually produces larger layer thickness and rougher surface features. Due to the high temperature in the building room, EBM printing parts may not need to be heat-treated after printing to relieve stress.

Fourth, material spraying

△ material injection

Material ejection is a 3D printing process in which tiny droplets of material are deposited and then solidified or solidified on the building board. Use photopolymer or wax droplets that will cure when exposed to light to build objects one layer at a time. The nature of the material spraying process allows different materials to be printed on the same object. One application of this technology is to manufacture parts with various colors and textures.

● Types of 3D printing technology: material ejection (MJ) and nanoparticle ejection (NPJ)

● Material: photosensitive resin (standard, pouring, transparent, high temperature resistant), wax.

● Dimensional accuracy: ±0.1 mm

● Common applications: full-color product prototypes, prototypes similar to injection molds, low-running injection molds, medical models, and fashion.

● Advantages: textured surface finish, full color and various materials available.

● Disadvantages: Limited materials are not suitable for mechanical parts requiring precision, and the cost is higher than other resin technologies used for visual purposes.

1. material injection (M-Jet)

△Stratasys’s material jet 3D printing parts

Material jet of polymer (M-Jet) is a 3D printing process, in which a layer of photosensitive resin is selectively deposited on the building board and cured by ultraviolet (UV). After one layer is deposited and solidified, the building platform reduces the thickness of one layer, and the process is repeated to build 3D objects. M-Jet combines the high precision of resin 3D printing with the speed of wire 3D printing (FDM) to create parts and prototypes with realistic colors and textures.

All material jet 3D printing technologies are not exactly the same. There are differences between printer manufacturers and proprietary materials. M-Jet machines deposit building materials from multiple rows of print heads in a line-by-line manner. This method enables the printer to manufacture multiple objects on a line without affecting the construction speed. As long as the models are arranged correctly on the construction platform and the space in each construction line is optimized, M-Jet can produce parts faster than many other types of resin 3D printers.

△ Material jet 3D printers from Stratasys, DP Polar/3D Systems and Mimaki.

The object made by M-Jet needs support, and it is printed by soluble materials at the same time during the construction process, which is removed in the post-processing stage. M-Jet is one of the few 3D printing technologies, which can provide objects made of multi-material printing and full color. There is no amateur version of the material jet machine. These machines are more suitable for professionals of automobile manufacturers, industrial design companies, art studios, hospitals and all kinds of product manufacturers. They want to create accurate prototypes to test concepts and bring products to market faster. Unlike barrel polymerization technology, M-Jet does not need post-curing, because the ultraviolet rays in the printer will completely cure each layer.

Aerosol jet

Aerosol Jet is a unique technology developed by a company named Optomec, which is mainly used for 3D printing electronic products. Components such as resistors, capacitors, antennas, sensors and thin film transistors are printed by aerosol spraying technology. It can be roughly compared to painting, but it is different from industrial coating process in that it can be used to print complete 3D objects.

Put the electronic ink into the atomizer, which will produce droplets with a diameter between 1 and 5 microns. Then the aerosol mist is transported to the deposition head and focused by the sheath gas, thus producing a high-speed particle spray. Because the whole process uses energy, this technology is sometimes called directional energy deposition, but because the material is in the form of droplets in this case, we include it in the material injection.

Plastic free forming

Arburg, a German company, has created a technology called plastic freeform molding (APF), which is a combination of extrusion technology and material injection technology. It uses commercially available plastic particles, which are melted in the injection molding process and moved to the unloading unit. The closing of the high-frequency nozzle produces a rapid opening and closing movement of up to 200 plastic droplets with a diameter of 0.2 to 0.4 mm per second. The droplets combine with the hardened material when cooling. Generally speaking, no post-treatment is needed. If supporting materials are used, they must be removed.

2. Nanoparticle Jet (NPJ)

△ Metal parts created by using nanoparticle injection technology and XJet 3D printer.

NanoParticle Jetting (NPJ) is one of the few proprietary technologies that are difficult to classify. It was developed by a company named XJet. It uses a printhead array with thousands of inkjet nozzles to spray millions of ultrafine material droplets onto the ultra-thin building tray at the same time, and simultaneously spray supporting materials. Metal or ceramic particles are suspended in a liquid. This process takes place at high temperature, and the liquid evaporates when spraying, leaving mostly metal or ceramic materials. Only a small amount of adhesive remains in the generated 3D parts, and these adhesives are removed in the post-sintering treatment.

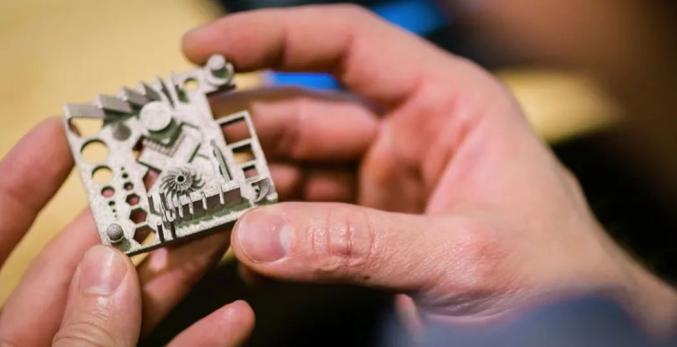

V. Adhesive spraying

△ adhesive spraying

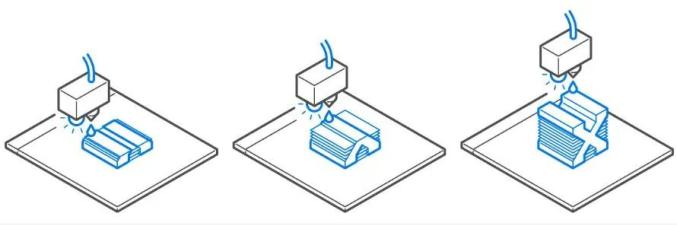

Adhesive spraying is a 3D printing process in which liquid adhesive selectively adheres to areas of a layer of powder. This technology type has the characteristics of powder bed fusion and material injection. Similar to PBF, adhesive spraying uses powder materials (metal, plastic, ceramics, wood, sugar, etc.), and like material spraying, liquid adhesive polymer is deposited from an inkjet. Whether it is metal, plastic, sand or other powder materials, the adhesive spraying process is the same.

First, the recoating blade coats a thin layer of powder on the building platform. Then, a print head with an inkjet nozzle passes over the bed and selectively deposits adhesive droplets to bond the powder particles together. After the layer is completed, the building platform moves down and the blade recoats the surface. Then repeat the process until the whole part is completed.

Adhesive spraying is unique in that there is no heat in the printing process. The binder acts as glue that binds the polymer powders together. After printing, the parts are wrapped in unused powder, which usually remains for curing. Then the parts are taken out of the powder bin, and the excess powder is collected and can be reused. From here on, according to different materials, post-treatment is needed, except for sand, which can usually be directly used as cores or molds from printers. When the powder is metal or ceramic, the post-treatment involving heating will melt the binder, leaving only the metal. Post-treatment of plastic parts usually includes coating to improve surface finish. You can also polish, paint and grind the polymer adhesive spraying parts.

The adhesive has high spraying speed and high productivity, so it can produce a large number of parts more economically and efficiently than other AM methods. Metal adhesive spraying can be used for a variety of metals and is very popular in end-use consumer goods, tools and bulk spare parts. However, the material selection of polymer adhesive injection is limited, and the structural performance of the produced parts is low. Its value lies in being able to make full-color prototypes and models.

● Subtypes of 3D printing technology: metal adhesive spraying, polymer adhesive spraying and sand adhesive spraying.

● Material: sand, polymer, metal, ceramics, etc.

● Dimensional accuracy: 0.2 mm (metal) or 0.3 mm (sand)

● Common applications: functional metal parts, full-color models, sand castings and molds.

● Advantages: low cost, large building volume, functional metal parts, excellent color reproduction, fast printing speed and unsupported design flexibility.

Disadvantages: It is a multi-step process for metals, and polymer parts are not durable.

1. Metal adhesive spraying

△ HP stainless steel 3D printing parts using metal spraying technology

Binder Jetting can also be used to manufacture solid metal objects with complex geometries, which is far beyond the capabilities of traditional manufacturing technologies. Metal adhesive spraying is a very attractive technology, which can be used to mass-produce metal parts and realize lightweight. Since adhesive spraying can print parts with complex patterns instead of solids, the weight of the parts obtained is greatly reduced, but the strength remains unchanged. The porosity characteristics of adhesive injection can also be used to realize lighter end parts for medical applications, such as implants.

Generally speaking, the material properties of metal binder sprayed parts are equivalent to those of metal parts produced by metal injection molding, and it is one of the most widely used manufacturing methods in mass production of metal parts. In addition, the adhesive spraying parts show higher surface smoothness, especially in the internal channels.

△ Metal adhesive jet 3D printer produces fine solid metal parts for end-use applications.

Metal adhesive spraying parts need secondary processing after printing to obtain good mechanical properties. Just coming out of the printer, the parts are basically composed of metal particles bonded together with polymer adhesives. These so-called "green parts" are too fragile to be used as they are. After the printed parts are taken out of the metal powder bed (called the process of powder removal), they will be heat-treated in the furnace (called the process of sintering). Both printing parameters and sintering parameters are adjusted according to the geometry, material and required density of specific parts. Bronze or other metals are sometimes used to penetrate the voids in the adhesive spraying parts, thus achieving zero porosity.

2. Plastic adhesive spraying

△ Plastic adhesive spraying

Plastic adhesive spraying is a process very similar to metal adhesive spraying, because it also uses powder and liquid adhesive, but its application is quite different. After printing, plastic parts will be taken out of their powder beds and cleaned, and usually can be used without further treatment, but these parts lack the strength and durability in the 3D printing process. The plastic adhesive spraying part can be filled with another material to improve the strength. Using polymers for adhesive spraying can produce multicolor parts for medical modeling and product prototyping.

3. Sand binder spraying

△ sand binder injection

Sand adhesive spraying and plastic adhesive spraying are different in printer and printing process, so they are distinguished here. Producing large sand casting molds, molds and cores is one of the most common uses of adhesive injection technology. The low cost and speed of this process make it an excellent solution for foundry, because it is difficult to produce fine pattern designs in a few hours with traditional technology.

The future of industrial development constantly puts high demands on foundries and suppliers. Sand 3D printing is at the beginning of its potential. After printing, the printer needs to remove the cores and molds from the construction area and clean them to remove any loose sand. The mold can usually be ready for casting immediately. After casting, the mold is disassembled and the final metal parts are removed.

4. Multi-jet fusion (MJF)

△ BASF and HP cooperated to develop a new industrial grade polypropylene for MJF.

Another unique and brand-specific 3D printing process, which is not easy to fall into any existing category, is actually not adhesive spraying, and this is HP’s Multi Jet Fusion. MJF is a polymer 3D printing technology, which uses powder materials, liquid fusion materials and refiners. The reason why it is not considered as adhesive spraying is that the heat is increased in this process, which will produce parts with higher strength and durability, and the liquid is not completely adhesive. The name of this process comes from multiple inkjet heads that perform the printing process.

In the process of Multi Jet Fusion printing, the printer lays a layer of material powder, usually nylon, on the printing bed. After that, the inkjet head passes through the powder and deposits a melting agent and a refining agent on it. Then the infrared heating device moves on the printed matter. No matter where the flux is added, the lower layers will melt together, while the areas with refiners will remain powdery. The powdery part falls off to produce the required geometry. This also eliminates the need for modeling support, because lower layers support layers printed on them. In order to complete the printing process, the whole powder bed and the printing parts in it are moved to a single processing station, and most of the loose unmelted powder is evacuated and can be reused.

Multi Jet Fusion is a multifunctional technology, which has been applied in many industries such as automobile, medical care and consumer goods.

△HP Jet Fusion 5200 series is one of the many sizes and styles of HP Multi Jet Fusion 3D printer (source: HP).

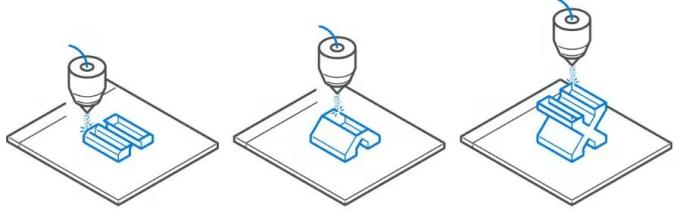

Six, powder directional energy deposition

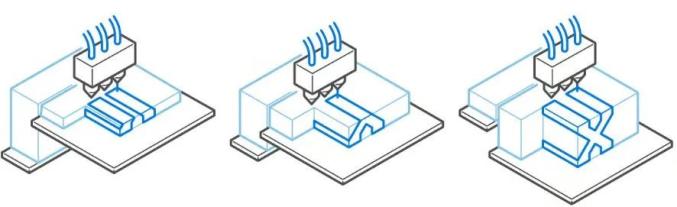

Directional Energy Deposition (DED) is a 3D printing process. Metal materials are supplied and melted by powerful energy while being deposited. This is one of the most extensive 3D printing categories, including many subcategories, depending on the material form (wire or powder) and energy type (laser, electron beam, arc, supersonic, heat, etc.). Essentially, it has a lot in common with welding.

This technology is used for layer-by-layer printing, usually followed by CNC machining to achieve stricter tolerances. The combination of DED and CNC is very common. There is a sub-type of 3D printing called hybrid 3D printing, which contains a hybrid 3D printer with DED and CNC units in the same machine. This technology is considered to be a faster and cheaper substitute for small-batch metal castings and forgings, as well as a key maintenance for offshore oil and gas industries, aerospace, power generation and utilities.

△DED metal 3D printing technology can quickly create a solid metal part, and then it can be processed to strict tolerances.

● Subtypes of directional energy deposition: powder laser energy deposition, wire arc additive manufacturing (WAAM), wire electron beam energy deposition and cold spraying.

● Materials: various metals, wires and powder forms.

● Dimensional accuracy: ±0.1 mm

● Common applications: repairing high-end automotive/aerospace components, functional prototypes and final components.

● Advantages: high stacking rate, and the ability to add metal to existing components.

● Disadvantages: Because the supporting structure cannot be made, it is impossible to make complex shapes, and the surface smoothness and accuracy are usually poor.

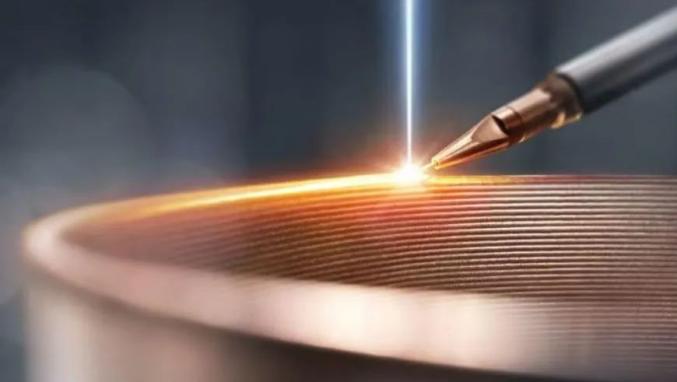

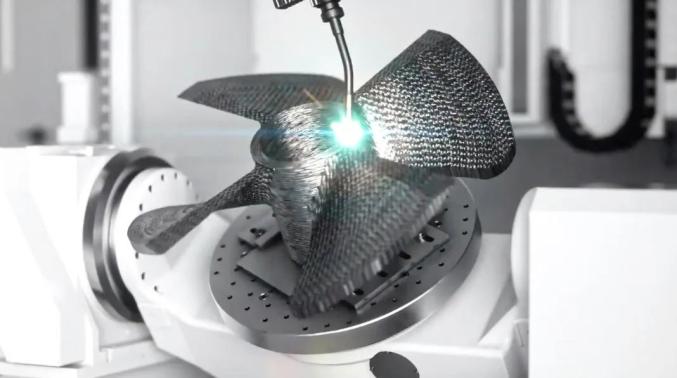

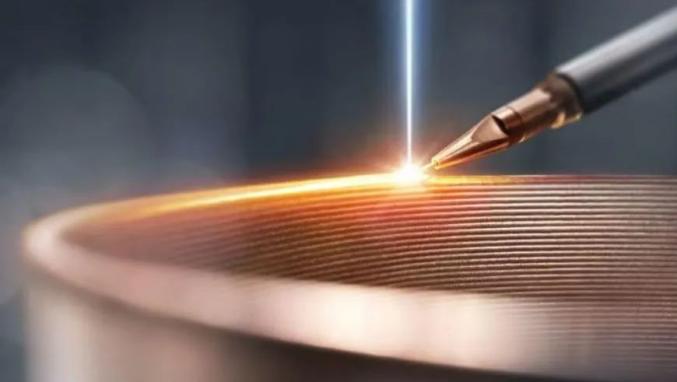

1. Laser directed energy deposition

△ 3D printing metal using laser and powder metal

Laser-directed energy deposition (L-DED), also known as laser metal deposition (LMD) or laser engineering net shaping (LENS), uses metal powder or metal wire sent through one or more nozzles and melted by powerful laser to build platforms or metal parts. With the movement of nozzle and laser or the movement of parts on the multi-axis turntable, objects will be piled up layer by layer. The construction speed is faster than that of powder bed melting, but it will lead to the decrease of surface quality and precision, and usually requires a lot of post-processing. Laser DED printers usually have a sealed chamber filled with argon to avoid oxidation. When dealing with less reactive metals, they can also operate with only local argon or nitrogen.

Metals commonly used in this process include stainless steel, titanium and nickel alloy. This printing method is usually used to repair high-end aviation and automobile parts, such as jet engine blades, but it is also used to produce whole parts.

△Meltio M450 wire feeding laser DED 3D printer, Optomec LENS CS 600 metal powder feeding laser DED 3D printer and DMG Mori Lasertec 65 DED powder feeding laser DED 3D printer.

2. Electron beam directional energy deposition

△ electron beam DED 3D printing

Electron beam DED, also known as linear electron beam energy deposition, is a 3D printing process very similar to laser DED. It is carried out in a vacuum chamber and can produce very clean and high-quality metals. When a wire passes through one or more nozzles, it will be melted by the electron beam. The layer is constructed separately, the electron beam forms a tiny molten pool, and the welding wire is fed into the molten pool by a wire feeder. When dealing with high-performance metals and active metals (such as copper, titanium, cobalt and nickel alloy), electron beam is selected for DED.

DED machines are virtually unlimited in print size. For example, Sciaky, a 3D printer manufacturer, has an EB DED machine that can produce parts nearly 6 meters long at a speed of 3 to 9 kilograms of materials per hour. Electron beam DED is touted as one of the fastest methods to manufacture metal parts, although it is not the most accurate, which makes it an ideal machining technology to build large structures (such as fuselage) or replace parts (such as turbine blades).

△ 3D printing of wire by electron beam deposition

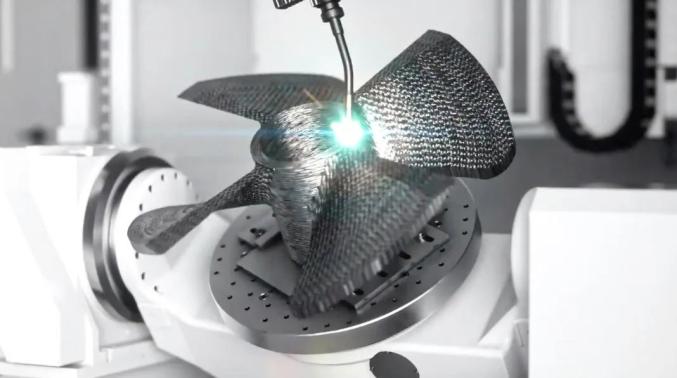

3. Line-controlled energy deposition

△Gefertec arc additive manufacturing (WAAM) printing

Wire Directed Energy Deposition, also known as wire arc additive manufacturing (WAAM), is a kind of 3D printing, which uses energy in the form of plasma or arc to melt the metal in the form of wire, and deposits the metal layer by layer on a surface, such as a multi-axis turntable, to form a shape by a robotic arm. This method is chosen instead of the similar technology of laser or electron beam because it does not need a sealed chamber and can use the same metal (sometimes the same material) as traditional welding.

Direct energy deposition is considered to be the most cost-effective choice in DED technology, which can use the existing arc welding robot and power supply, so the entry threshold is relatively low. But unlike welding, this technology uses complex software to control a series of variables in the process, including the thermal management of the robot arm and the tool path. This technology has no supporting structure to be removed, and the finished parts are usually CNC machined when necessary to achieve strict tolerance or surface polishing.

△Gefertec and WAAM3D’s line arc additive manufacturing 3D printer.

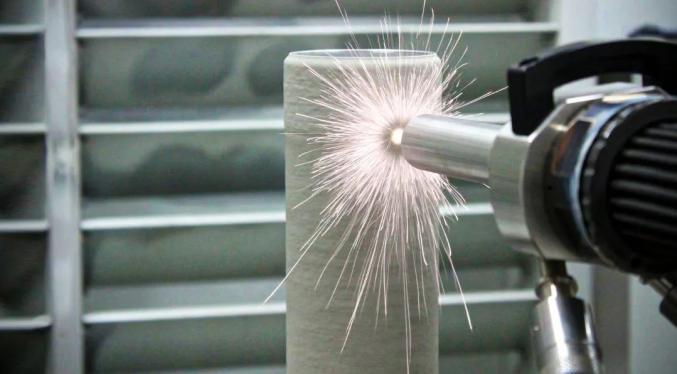

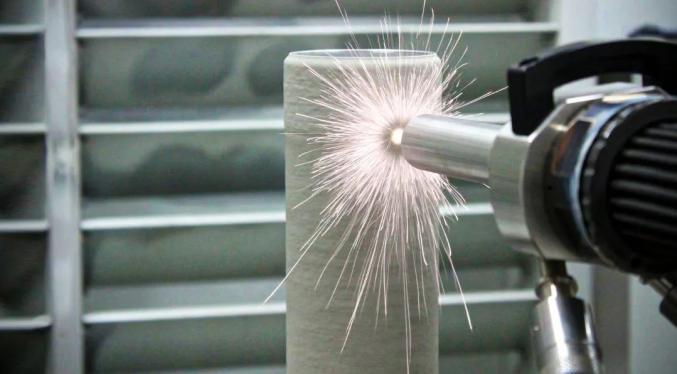

4. Cold spraying

△ cold spraying

Cold spraying is a DE3D printing technology, which sprays metal powder at supersonic speed to combine them without melting, and hardly produces thermal cracks or thermal stress. Since the early 2000s, it has been used as a coating process, but recently, several companies have used cold spraying for additive manufacturing, because it can print at a speed 50 to 100 times higher than that of a typical metal 3D process and does not require inert gas or vacuum chamber.

Like all DED processes, cold spraying will not produce prints with good surface quality or details, but the parts can be used directly from the printing bed.

5. Melting direct energy deposition

△ Melting Direct Energy Deposition: Aluminum parts printed by ElemX 3D liquid metal of Xerox.

Melting direct energy deposition is a 3D printing process, which uses heat to melt metal (usually aluminum) and then deposits it layer by layer on the building board to form 3D objects. The difference between this technology and metal extrusion 3D printing is that metal raw materials containing a small amount of polymer are used for extrusion, so that the metal can be extruded. Then the polymer is removed in the heat treatment stage, and pure metal is used to melt DED. One can also compare molten or liquid DED to material injection, but instead of a series of nozzles to deposit droplets, liquid metal usually flows out from the nozzles.

Variants of this technology are being developed, and molten metal 3D printers are rare. The advantage of using heat to melt and then deposit metal is that it can use less energy than other DED processes, and it is possible to directly use recycled metal as raw material instead of metal wire or highly processed metal powder.

VII. Lamination of sheets

△ Sheet lamination

Sheet lamination is technically a form of 3D printing, which is quite different from the above technologies. Its function is to stack and laminate very thin pieces of material together to create 3D objects or stacks, and then cut them by machinery or laser to form the final shape. The layers of materials can be fused together in a variety of ways, including heating and sound, depending on the material, ranging from paper to polymer to metal. When the parts are laminated and then laser cut or processed into the required shape, it will produce more waste than other 3D printing technologies.

Manufacturers use sheet lamination to produce cost-effective non-functional prototypes at a relatively high speed, which can be used in battery technology and composite materials, because the materials used can be interchanged in the printing process.

● Types of 3D printing technology: Laminated Object Manufacturing (LOM) and Ultrasonic Consolidation (UC)

● Materials: paper, polymer and sheet metal.

● Dimensional accuracy: ±0.1 mm

● Common applications: non-functional prototyping, multi-color printing and casting.

● Advantages: rapid production and compound printing.

● Disadvantages: low precision, much waste, and some parts need post-production.

Laminated additive manufacturing

△ Laminated additive manufacturing

Lamination is a 3D printing technology, in which sheets of materials are laminated and glued together, and then the layered objects are cut into the correct shape with a knife (or laser or CNC router). This technology is less common nowadays, because the cost of other 3D printing technologies has decreased, and the speed and ease of use have greatly increased.

△BCN3D viscous lithography manufacturing (VLM) 3D printing process using resin (source: BCN3D)

Viscosity lithography (VLM): VLM is a patented 3D printing process of BCN3D, which can laminate a thin layer of high-viscosity photosensitive resin onto a transparent transfer film. The mechanical system allows the resin to be laminated from both sides of the film, so that different resins can be combined to obtain a multi-material part and an easily detachable support structure. This technology has not been commercialized, but it can also belong to one of the laminated 3D printing technologies.

Composite-based additive manufacturing (CBAM):Startup Impossible Objects applied for a patent for this technology, which combines carbon, glass or Kevlar mats with thermoplastics to manufacture parts.

Selective Laminated Composite Manufacturing (SLCOM): Envision Tec, now called ETEC, owned by Desktop Metal, developed this technology in 2016, which uses thermoplastics as the base material and woven fiber composite.

Note: There are many kinds of 3D printing technologies. These are the seven most common additive manufacturing technologies in 3D printing, which do not cover all 3D printing technologies in the market.

Original title: "7 mainstream 3D printing technologies, all of which can be understood"

Read the original text